|

™ |

|

Copyright © 2003-2018 SYSTEMS AND MAGIC |

|

M A D E I N I T A L Y |

|

PEARL |

|

√ |

|

function and emotion |

|

BlackNoise Mains Filters

Energy Distributors

Mains Cables

PEARL

Accessories

Publications

|

|

The PEARL is the latest of our AC cables and represents their “TOP”, their outermost expression: it’s the most complete and performing one.

With an extraordinary low contact resistance and with the internal conductors of well 5mmq for phase and neutral (even more for the earthing wire), the PEARL is at ease even in the most demanding power conditions: big monoblocks, integrated amps or huge HT multichannel power gear.

In the same time, the completely shielded build achived not only with two different shields (silvered copper mesh + aluminium foil) but also with the help of plugs fully made in aluminium, allows the PEARL thanks to its very low noise level, to be an equally well performer with the most delicate gear too, like phono-preamps, line preamps and CD readers.

The special internal insulation with a very low energy storage add its contribution, making the PEARL very “quick” in delivering power especially during random and abrupt energy requests. |

|

PEARL DETAILS

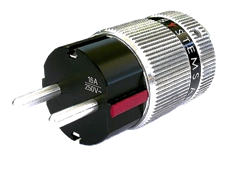

The PEARL uses unique plugs, built especially for this cable. They have been made with the clear aim to maximize two well defined electrical parameters: minimum possible resistance and maximum possible shielding. Let’s see how. |

|

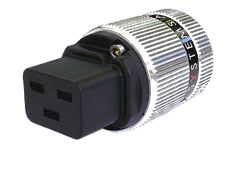

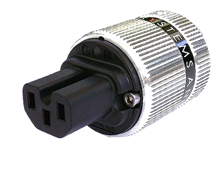

At this time, the available plugs are the Schuko (type F), 20A IEC (type C19) and 10A IEC (type C15). |

|

The IACS Standard

IACS means International Annealed Copper Standard, the unit of measure of electrical conductance for metals and metal alloys that settles annealed copper to a 100% reference value.

Silver (which is an even better conductor than copper) has a conductance of 106% of copper, while nickel (widely used as a finishing coat for plugs and sockets), ranks 16th, less than 1/4 of the copper conductance!

The IACS unit of measure is of very practical use: the scientific standard for electrical conductance is the siemens, but in our example using it to compare copper and rhodium (0.596 x 106/cm ohm siemens for copper against 0.211 x 106/cm ohm siemens for rhodium) it’s not of immediate comprehension while it is instead so using the IACS standard.

The following table lists the first 29 elements and alloys in order of decreasing electrical conductance:

|

|

THE CONTACTS

The minimum electrical resistance means being able to deliver the maximum energy transfer, especially dinamically. Within plugs, this is obtained with a careful choosing of materials together with achieving the widest possible contact area between plug and socket.

All PEARL contacts (therefore including the earth one) have been made in silver plated pure copper, a choice fully against the current trend that suggests, in both plugs and sockets top models, a mirror polished rhodium plating over a brass or, occasionally, a bronze base.

Silver is by far the best electric conducting material (it has the least electrical resistance), copper comes immediately after: contacts made in this way have an electric resistance up to six times less than the corresponding ones made of rhodiated, nickelated or golden plated brass or bronze.

Rhodium is much less conductive than copper, only 38,4% of it, a little more than a third (IACS* standard)! The effect is that the area of a rhodium contact have to be almost *tripled* to be equal to a copper contact! Gold itself, widely used in contact plating, reaches only 75% of copper conductivity, aluminium little more than 60%, nickel doesn’t reach 25%, brass is 28% and phospor bronze way down to 15%. Naturally, in comparison with silver, all these metals have even less favorable ratios.

Another very important point is related to the amount of contact area between plug and socket. Obviously, the more the contact area, the more the conducibility, the less the electrical resistance. We asked ourselves: how could we increase the contact area if the physical dimensions of all contacts are regulated by standards and cannot be changed? The only answer is using a soft metal for the contacts that “gives” mechanically a little at the time of insertion.

Metal surfaces at a microscopic level are not at all smooth even if they appear so to the touch. The surface instead appears fully made of minute “peaks” and corresponding “valleys”. When the plug surface mates with the socket one, many empty areas are left: in fact, there is true contact only where mutual irregularities “touch” themselves. Then again silver and copper, thanks to their pliability, turn out to be optimal to this purpose.

When a silver/copper contact is inserted in a socket, its pliability is such that its minute “peaks and valleys” imperceptibly “give in” and blend with the corresponding ones of the socket contacts (whatever metal they are made of) to the full advantage of conducibility. The net effect is such that the contact area is wider, without any apparent external dimension change!

Rhodium, on the contrary, is extremely tough and its hardness greatly reduces the likehood to “give in” in the contact zones. Moreover, this factor together with mirror polishing, strongly decreases “peaks and valleys” achieving, overall, an even smaller contact area!

It’s likely that rhodium recovers a great deal of the contact area in the situations where *THE SOCKET TOO* (and not only the plug) is rhodiated and mirror polished, this time for the opposite reason: the greatly diminished number of peaks and valleys on both metal surfaces favours the contact on larger *FLAT* areas than before. However, given the same dimensional relations between plug and socket, in the most favourable event, the contact area would be the same of the silvered plug and what would now make the difference would only be the electrical resistance of rhodium versus silver, totally in favour of this last one.

From our point of view there is no “real” added value in using rhodium, set aside an undeniable aesthetic value: mirror polished rhodium is truly impressive to be seen! :-)

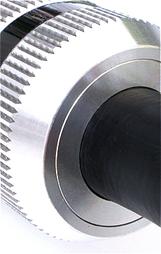

THE SHELL

Differently than most AC cables that have plugs made of plastic materials, the PEARL boasts a fully milled aeronautic aluminium shell with a minimum thickness of 3mm. Nowstanding, the external body is barely larger than the plugs it hosts, so the whole easily fits in any electronic socket.

It can be hinted then, apart from mechanical ruggedness, that the use of aluminium transforms the shell in a electromagnetic shield, natural extension of the AC cable shields, allowing the interference protection to extend up to where phisically possible, almost inside the electronics themselves.

Having the metallic shell connected to the cable shield it’s not an obvious property: the very few AC plugs around that have their outer shells made of aluminium (or any other conductive material) DO NOT have it connected to earth.

THE SHIELDING

Shielding it’s a constant in our AC mains cables view, from the most price conscious one up to the most pricey and the PEARL makes no exception. In this case, in fact, the shielding is doubled: a very tight silvered-copper mesh, and a second one in aluminium foil.

Shielding mains cables means avoiding their internal electromagnetic fields radiating outside the cable themselves, inducing noise in the nearby signal, power an even other UNSHIELDED mains cables! It is always undervaluated, but the audio electronics themselves are the ones that makes most of the noise and inject it on the mains cables: shielding not necessarily is there to protect from “outside” noise!

The two different shields, their “stretching” to include both aluminium plugs and the semi-balanced connection (shields connected only at the mains entrance side) allows the PEARL to have the best possible protection either from the outside and from the “inside” environments.

See point 9 in the FAQ to investigate our thoughts about mains cable shielding.

THE WIRES AND THE INSULATION

With a 5 square millimiters both for phase an neutral the PEARL is second to none in its power delivering ability; the earthing wire, far from being neglected, has an even wider area! The only small disadvantage derived from such substantial conductors is the increased general stiffness: the PEARL it’s not an easy manageable cable!

Copper is the material used for the conductors: silver would have had a slightly lower resistance (about 6%) but at an absolutely impossibile price. The cable resistance, nonetheless, remains extremely low, barely 4 milliohm/meter first and foremost to the efforts spent to ensure plug contacts of absolute quality.

The insulators used are polyethylene (PE) and teflon (PTFE). Both of them guarantee an extremely low reactive energy storage, substantially lower than the widely used PVC (polyvynylchloride), with the net result of a much fresher and “speedier” response to sudden energy requests.

Finally it’s the geometry of the cable itself, with the unusual alternation of the phase, neutral and earth wires that add its contribuition to the PEARL readiness and noiselessness. |

|

Read the PEARL brochure in PDF format |

|

The unique silver/copper/aluminium PEARL plugs made especially for this cable. |

|

An extremely neat detail of the back finishing. |

|

The PEARL, defined “the cable that doesn’t play” by the magazine “The Absolute Audiophile”, appears neutral and coherent over all frequency bands, with a fresher, more reactive and spontaneous musical proposition. The appealing extension on the highs without any harshness trace, comes together with a tight, clear and polychrome bass range in a wide, augmented spaciousness and oxygenation of the acoustical scene reconstruction.

The PEARL, have been engineered to be, above all, *balanced*, meaning no exasperation of particular audio feature, materials or price. The PEARL it’s not an economic product, but it bears a solid matter-of-factness in its design details that leads to an especially neutral and effective product.

What follows are, in detail, all facets that takes part in making the PEARL a truly unique mains cable. |

|

The PEARL in its semi-transparent case. |

|

These plugs are also used, due to an exclusive agreement, with the TOP AC cables made by White Gold. |

|

email: info@systemsandmagic.com |

|

S Y S T E M S A N D M A G I C |

|

N° |

Element |

Simbol |

Periodic Number |

IACS % |

|

1 |

Silver |

Ag |

47 |

105.70 |

|

2 |

Copper |

Cu |

29 |

100.00 |

|

3 |

Gold |

Au |

79 |

75.84 |

|

4 |

Aluminum |

Al |

13 |

63.26 |

|

5 |

Beryllium |

Be |

4 |

52.52 |

|

6 |

Calcium |

Ca |

20 |

50.00 |

|

7 |

Magnesium |

Mg |

12 |

37.92 |

|

8 |

Rhodium |

Rh |

45 |

35.40 |

|

9 |

Sodium |

Na |

11 |

35.23 |

|

10 |

Iridium |

Ir |

77 |

33.05 |

|

11 |

Tungsten |

W |

74 |

31.71 |

|

12 |

Molybdenum |

Mo |

42 |

31.38 |

|

13 |

Cobalt |

Co |

27 |

28.86 |

|

14 |

Brass |

|

|

28.00 |

|

15 |

Zinc |

Zn |

30 |

27.85 |

|

16 |

Nickel |

Ni |

28 |

23.99 |

|

17 |

Potassium |

K |

19 |

23.32 |

|

18 |

Cadmium |

Cd |

48 |

23.15 |

|

19 |

Ruthenium |

Ru |

44 |

22.99 |

|

20 |

Indum |

In |

49 |

19.46 |

|

21 |

Osmium |

Os |

76 |

18.29 |

|

22 |

Lithium |

Li |

3 |

18.12 |

|

23 |

Iron |

Fe |

26 |

16.66 |

|

24 |

Platinum |

Pt |

78 |

16.21 |

|

25 |

Palladium |

Pd |

46 |

15.94 |

|

26 |

Tin |

Sn |

50 |

15.39 |

|

27 |

Phosp. Bronze |

|

|

15.00 |

|

28 |

Rubidium |

Rb |

37 |

13.07 |

|

29 |

Chromium |

Cr |

24 |

12.99 |